Baseball is a sport that is heavily influenced not only by the players’ skills and tactics, but also by the equipment they use.

Among these, the ball is a very important element, and the number of seams in particular has a significant impact on play.

The seams of the ball are an element that players cannot ignore, as they affect the rotation and change of the pitch, the flight of the hit ball, and even how it is handled when defending.

This article will explain in detail the number of stitches on a baseball.

It covers a wide range of topics, from basic ball knowledge, to how the number of seams affects play, their role in pitcher and batter technique, to the latest research and technology in ball manufacturing.

目次

- 1 Basic knowledge of baseball

- 2 How many stitches does a baseball have?

- 3 The effect of the number of stitches

- 4 Number of stitches and pitcher’s technique

- 5 Number of stitches and batter response

- 6 The number of stitches and the manufacturing process of the ball

- 7 Recent research on stitch count and future prospects

Basic knowledge of baseball

The baseball is a vital component at the heart of the sport of baseball.

By understanding its history and evolution, its structure and materials, as well as the regulations regarding size and weight, you can gain a deeper understanding of the depth and appeal of baseball.

Here we will explain in detail the basic knowledge about baseballs.

The history and evolution of baseball

The history of the baseball has evolved alongside the history of baseball itself.

Early baseballs were handmade and were made from a variety of different materials and came in a variety of different sizes.

In the early 19th century in America, balls wrapped in cloth or leather were commonly used, but their shape and hardness varied greatly depending on the region and maker.

In the 1870s, balls became more standardized and balls based on official rules began to be used.

This helped to keep the game fair and baseball’s popularity soared.

In the early 20th century, balls with rubber cores were introduced, increasing the distance the ball could travel and improving pitcher technique.

Modern baseballs are manufactured to exacting standards, resulting in extremely high levels of precision and quality.

As technology advances, the manufacturing process for balls has become more sophisticated, allowing for a steady supply of balls with consistent performance.

Baseball structure and materials

Modern baseballs are made up of multiple layers and are extremely sophisticated in their construction.

The basic structure is as follows:

-

Core :

- The core of the ball is made of rubber or cork, which provides the ball with its basic resilience. The core material and density determine the ball’s flight distance and elasticity.

-

Thread winding layer :

- The core is wrapped in layers of very fine wool or polyester yarn, which help the ball maintain its shape and make it more durable.

-

cover :

- The ball’s outermost layer, usually made from horsehide or cowhide, is very hard and durable, and the cover has stitching that determines the ball’s aerodynamic properties.

Ball size and weight regulations

The size and weight of baseballs are strictly regulated by official rules.

This ensures fairness in all matches.

-

size :

- The diameter of the ball is set to be between 2.86 inches (7.3 cm) and 2.94 inches (7.5 cm). This size range is designed to ensure the ball is properly gripped and easy to throw.

-

weight :

- The weight of the ball must be between 5 ounces (about 142g) and 5.25 ounces (about 148g), which is the weight range that makes it easier for the pitcher to control the ball and for the batter to hit it.

These regulations are critical to providing a consistent playing environment in the game of baseball.

Differences in ball size and weight have a significant effect on the pitcher’s delivery and the batter’s hitting, so they are strictly controlled in official games.

Overall, baseballs have strict regulations regarding their construction, materials, size and weight that help ensure the quality and fairness of the sport.

By understanding the history and evolution of the ball, you will be able to appreciate the depth of baseball.

Please refer to the latest information, reaffirm the importance of baseballs, and apply it to your play.

How many stitches does a baseball have?

A baseball’s seams are an important element that greatly affect how a pitcher throws the ball and how a batter hits the ball.

The number and shape of the seams change the ball’s aerodynamic properties, affecting the spin, deflection and even flight of the ball when thrown.

Here we will explain in detail the number of seams on a baseball, its definition and calculation method, the regulations and rules, and the differences between Major League Baseball and Japanese professional baseball.

How to define and calculate the number of stitches

The number of stitches on a baseball refers to the total number of stitches on the surface of the ball.

Typically, the seams on a ball are formed by sewing two pieces of leather together, and the number of stitches follows certain rules.

-

Definition :

- Stitch count refers to the number of stitches that go around the circumference of the ball. Typically, a baseball has 108 stitches, which are used to sew the two hemispheres of the ball together.

-

Method of calculation :

- The method for calculating the number of stitches is to count the number of stitches that go around the circumference of the ball. Since each stitch is spaced at a regular interval, it is possible to count the exact number. 108 stitches is the standard for a typical baseball for official play.

Stitch count regulations and rules

The number of stitches on a baseball is strictly regulated by official rules.

This ensures that every match is played under the same conditions.

-

Regulations :

- Both Major League Baseball (MLB) and Nippon Professional Baseball (NPB) regulate the number of stitches on a baseball to be 108. This is calculated by sewing the two halves of the ball together with 54 stitches, resulting in a total of 108 stitches.

-

rule :

- The seams on the ball are often sewn with red thread, as required by the official rules, to make it easier for the pitcher and batter to visually check the ball’s rotation.

- They also regulate the height and width of the stitching and the thickness of the thread, ensuring the ball’s aerodynamic properties remain consistent.

Differences between Major League Baseball and Japanese Professional Baseball

There are some differences between Major League Baseball (MLB) and Nippon Professional Baseball (NPB) regarding the seams of the balls.

These differences can also affect play.

-

Materials and manufacturing methods :

- MLB and NPB balls have slight differences in materials and manufacturing methods. For example, MLB balls are made from natural horsehide, while NPB balls are made from cowhide. This difference can affect the feel and durability of the ball.

-

Seam height :

- It is generally said that NPB balls have higher seams than MLB balls. Higher seam heights can give pitchers a better grip on the ball and increase the effectiveness of curveballs. This can result in differences in pitch control and curveball accuracy.

-

Aerodynamics :

- Different seam heights and shapes also affect the aerodynamic properties of the ball. Balls with higher seams have more air resistance, which makes them more likely to curve or break when pitched, making them more difficult for batters to hit.

Overall, the number of seams on a baseball is an important factor that has a significant impact on pitching and hitting.

Understanding the number of stitches and their characteristics as dictated by the official rules will allow players to handle the ball more effectively.

Knowing the differences between Major League Baseball and Japanese professional baseball will make it easier for you to adapt to playing in a different environment.

The effect of the number of stitches

The number of seams on a baseball has a significant impact on how the ball plays in all aspects: pitching, hitting and defense.

In particular, the number and placement of seams determines the quality of play, as they directly affect the rotation and change in the pitcher’s pitch, the feel of the hitter’s hit, and how the ball is handled when defending.

Here we will explain in detail the relationship between pitching rotation and breaking balls, their impact on batting, how to handle them when defending, and field play.

The relationship between pitch rotation and breaking balls

For a pitcher, the seams of the ball are very important.

The number and height of the seams directly affect the rotation and change of the ball.

-

Rotational Enhancement :

- The more stitches there are, the easier it is to get your fingers on the ball and put more spin on it. A ball with more spin, whether it’s a fastball or a curveball, is more stable in the air and you can throw it more accurately to the target point.

-

Curveball effect :

- The height and number of stitches also affect the behavior of a breaking ball. For example, the amount of change in a breaking ball, such as a curveball or slider, is determined by the pressure and rotation of the fingers on the stitches. A higher stitch height makes it easier to apply more spin, resulting in a sharper change in direction.

-

Use of air resistance :

- The seams of the ball create air resistance, giving pitches like the four-seam fastball and two-seam fastball their characteristic movement. The four-seam fastball has more seams that catch the air, creating a floating sensation, while the two-seam fastball has fewer seams, reducing air resistance and creating a sinking motion.

Impact on hitting

The seam of the ball is also important to the batsman.

It affects the quality of the ball, the distance it travels, and the feel of the hit.

-

Ball distance :

- Balls with high seams tend to have less air resistance and therefore less distance when hit, whereas balls with low seams have less air resistance and tend to have a greater chance of hitting the ball farther.

-

Hitting feel :

- The feel of the seams also affects the feedback the hitter gets when the ball hits the bat. If the seams feel good, the hitter can better gauge the spin and direction of the ball, making it easier to time his swing.

-

Ball rotation :

- The seams affect the rotation of the ball, which in turn changes the spin of the ball. A strong backspin makes the ball more likely to fly as a line drive, while a topspin makes it more likely to produce a grounder.

Defensive handling and field play

For the defender, the seams of the ball also affect the quality of field play.

Making good use of the seams is important to improve accuracy when catching and throwing the ball.

-

Catching stability :

- The seams of the ball will catch firmly on the leather of the glove, improving stability when catching the ball. A ball with more seams and a firmer feel will be less likely to slip when catching the ball.

-

Throwing accuracy :

- By using the seams to apply spin to the ball, you can improve the accuracy of your throw. A ball that the seams grip tightly will be easier to control the spin of and will fly straighter towards your target.

-

Field Play Efficiency :

- Defenders who understand how the seams affect ball movement can more easily predict the bounce and rotation of the ball, which allows for faster and more accurate field play.

The number of stitches has a direct impact on the performance of the baseball and the player’s technique.

Pitchers, batters and defensive players can improve the quality of their play by understanding the characteristics of the seams and using them to their advantage.

Keep up with the latest research and technology and make the most of the impact that number of seams can have.

Number of stitches and pitcher’s technique

The number of seams on a baseball has a significant impact on a pitcher’s technique.

Pitchers can skillfully use the seams to throw a variety of breaking balls and confuse the opposing batters.

Here we will explain in detail how to grip the seam and your pitching form, how to throw various curveballs and how to use the seam, as well as examples and technical explanations from professional pitchers.

Seam grip and pitching form

The way you grip the seam will vary depending on the type of pitch you are making and your purpose.

By learning the proper grip, you can impart ideal spin to the ball and achieve the desired change of direction.

-

Four-seam fastball :

- The four-seam fastball maintains stability and speed in the air by firmly gripping the seams of the ball with your fingers and applying strong rotation to the ball. To hold the ball, place your fingers on the seams and fix your thumb on the bottom of the ball. For your pitching form, it is important to swing your arm smoothly and create a powerful snap.

-

Two-seam fastball :

- The two-seam fastball gives the ball a lateral change by gripping the ball with fewer seams than the four-seam fastball. The grip is with the fingers on the inside of the seams and the thumb lightly touching the bottom. The pitching form is to release the ball from a slightly lower release point and use the rotation of the wrist to bring out natural seam movement.

-

Curveball :

- A curveball creates a sharp change of direction by gripping the seam of the ball tightly and applying vertical spin to it. To hold the ball, place your fingers on the outside of the seam and keep your thumb firmly in place. In your pitching form, use your wrist to give the ball topspin so that it drops sharply.

How to throw various curveballs and use seams

The way each type of curveball moves is determined by how the seams are used.

Below we will introduce some typical curveballs and how to use their seams.

-

slider :

- The slider is a ball that curves sharply to the side by applying horizontal rotation to the ball. To hold the ball, place your fingers on the outside of the seam and fix your thumb on the bottom of the ball. In the pitching form, snap your wrist to the side to give the ball a slice rotation.

-

Changeup :

- A changeup is a curveball that is thrown with the same form as a fastball, but with less velocity. The grip is with the fingers spread between the seams to reduce spin on the ball. The release point is lower and wrist movement is minimized.

-

Knuckleball :

- The knuckleball is a ball that creates an irregular curve by throwing it with almost no spin. The grip is to place the fingertips on the seam and support the ball with the pads of the fingers. In the pitching form, the wrist is fixed and the ball is released without giving any spin to it.

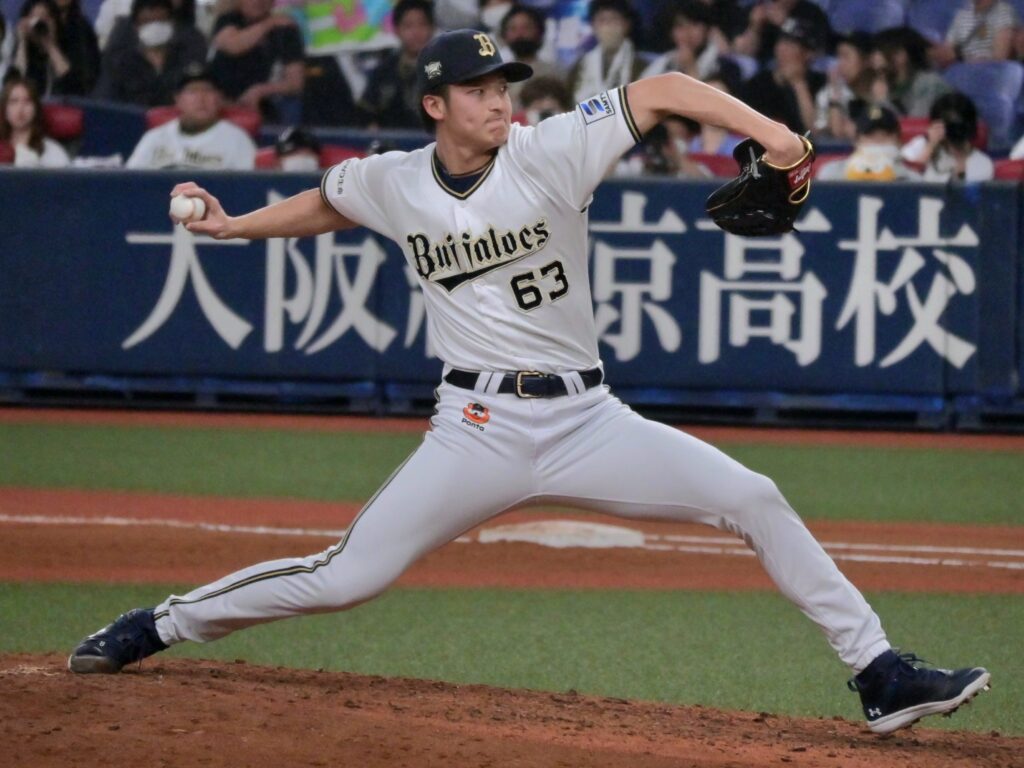

Examples and technical explanations from professional pitchers

Professional pitchers demonstrate advanced pitching techniques by making full use of the seams.

Below we will look at some examples of professional pitchers and their techniques.

-

Clayton Kershaw (Major League Baseball) :

- Kershaw is known as a master of the curveball. His curveball is made by using an exquisite grip on the seam and wrist, and by applying a sharp vertical rotation to the ball, it creates a sudden drop change. His pitching form is characterized by a powerful snap and a stable release point.

-

Yu Darvish (Japanese professional baseball) :

- Darvish is famous for using a variety of breaking balls. His slider is very skillful in using the seams and applying lateral rotation, making batters confused. In terms of his pitching form, his strengths are his flexibility in using his shoulders and elbows, allowing him to freely change his release point.

-

Justin Verlander (Major League Baseball) :

- Verlander is a master of the four-seam fastball. His fastball has a firm grip on the seams and a powerful snap, resulting in high speed and consistent rotation. His pitching form is characterized by a powerful step and full body coordination.

By learning the techniques of professional pitchers, you can understand how to use the seams and the importance of pitching form, and use these skills to improve your own.

Keep up with the latest information, gain a deeper understanding of the relationship between the number of stitches and pitching technique, and apply it to your play.

Number of stitches and batter response

The seams of a baseball are also an important factor for the batter.

By determining the seams of the ball, batters can predict the type and movement of the pitch and take appropriate action.

Here we will take a detailed look at the seam movement as seen by batters, hitting techniques that utilize the seams, and the experiences and tactics of professional batters.

Seam movement as seen by hitters

Batters can judge the type and movement of the pitch by looking at the seam movement of the ball.

The rotation and shape of the seam, in particular, are important visual cues for the batsman.

-

Identifying rotation :

- It is very important for a batter to be able to judge the rotation of a pitch. For example, a four-seam fastball has the characteristic that the seams of the ball look straight. This allows the batter to instantly tell that it is a fastball.

-

Curve ball identification :

- Curveballs and sliders have different rotation axes and unique seam movements. A curveball’s seam rotates vertically, making the ball appear to sink. A slider’s seam rotates horizontally, making the ball appear to slide sideways.

-

Seam Shape :

- Different pitches have different seam shapes. A changeup has irregular seams that tell the hitter it’s slow. A knuckleball has seams that barely move, so hitters can anticipate the irregular change.

Techniques for hitting using seams

Batsmen can take advantage of the seams of the ball to improve their hitting technique.

Below we will introduce some striking techniques that utilize seams.

-

Early verdict :

- By identifying the seams of the ball early, the batter can time his swing appropriately: for a fastball, he starts his swing the moment the seams look straight, and for a curveball, he figures out the rotation of the seams and adjusts his swing accordingly.

-

Swing Adjustments :

- It’s important to use the seams of the ball to adjust your swing. For fastballs, look closely at the seams and aim to hit the ball with the bat in the shortest distance. For curveballs, look at the rotation of the seams and delay your swing to get the timing right.

-

Improved contact accuracy :

- By being aware of the position of the seam, the accuracy of hitting the center of the ball is improved. The batter aims to hit the ball with the sweet spot of the bat by using the seam as a guide. This improves the distance and accuracy of the hit.

Professional batter’s experiences and tactics

Professional batters have advanced hitting techniques that utilize the seams.

Below are some stories and tactics from professional hitters.

-

Ichiro’s observation skills :

- Former major leaguer Ichiro is known for observing the seams of the ball very closely. He maintained a high batting average by instantly determining the rotation and change of the pitch and making the appropriate swing. Ichiro achieved stable batting by visually grasping the movement of the seams.

-

Mike Trout’s analytical skills :

- Mike Trout, an active major leaguer, has achieved excellent batting results by analyzing the movement of the seams and figuring out the pitcher’s habits. He observes the position and rotation of the seams before pitching, predicts the type of pitch, and adjusts his swing. Trout’s analytical ability supports his high on-base percentage and power.

-

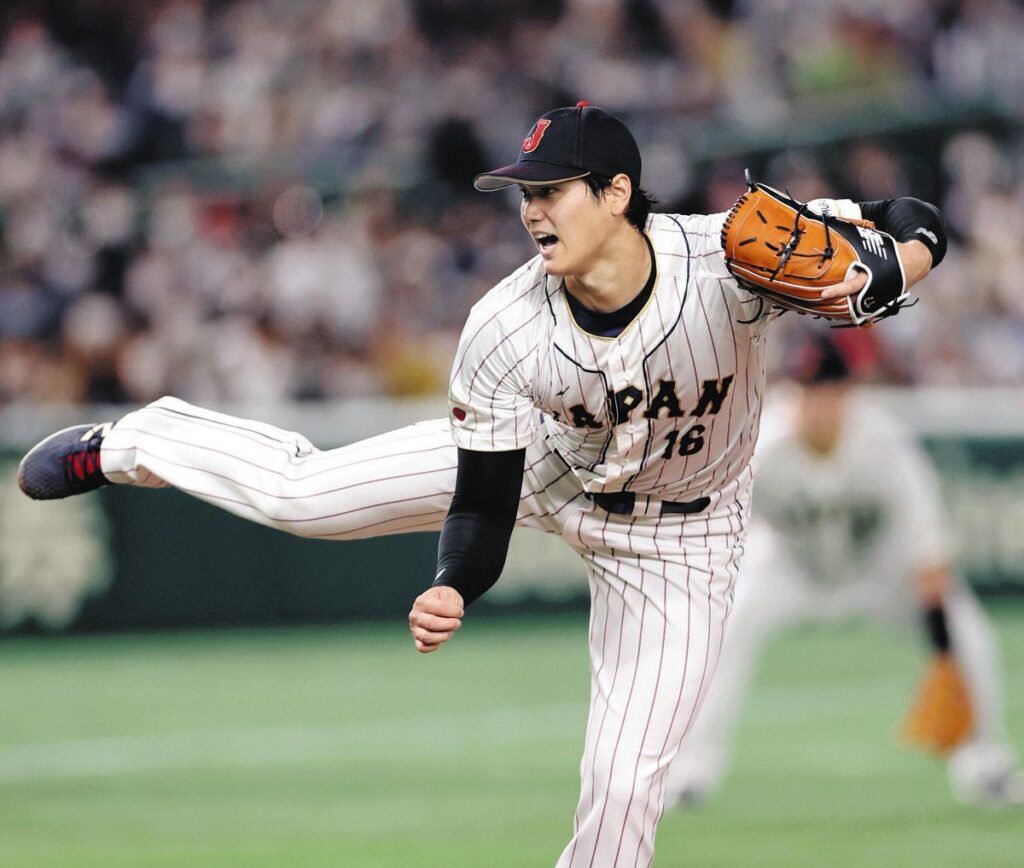

Shohei Ohtani’s Flexibility :

- Shohei Ohtani, who is active as a two-way player, has flexible hitting techniques that utilize the seams. He identifies the seams and adjusts his timing for fastballs, and reads the rotation of the seams and adjusts his swing for curveballs. Ohtani’s flexibility supports his diverse hitting style.

By learning the experiences and tactics of professional batters, you can acquire hitting techniques that effectively utilize the number and movement of seams.

Batsmen can improve the quality of their play by honing their visual skills in identifying seams and adopting the right hitting approach.

While keeping up with the latest information, try incorporating hitting techniques that utilize the seams to help you in your play.

The number of stitches and the manufacturing process of the ball

The manufacturing process for baseballs is very sophisticated and involves many steps to produce a high-quality ball.

In particular, the number of stitches and the method of formation have a significant impact on the performance of the ball.

This article will explain in detail the manufacturing process of the ball and how the seams are formed, the difference between hand and machine stitching, and quality control and inspection standards.

The manufacturing process of the ball and the formation of the seams

The manufacturing process for a baseball involves several main steps.

The process is explained in detail below.

-

Core formation :

- The ball has a rubber or cork core, which provides the ball’s basic bounce and elasticity, and is wrapped with thread to create a rigid center.

-

Thread winding layer :

- The core is wrapped in many layers of very fine wool or polyester yarn, which help the ball maintain its shape and make it more durable. The winding process has a major impact on the uniformity and performance of the ball.

-

Installing the cover :

- Over the wound layer are two hemispherical leather covers, usually made from horsehide or cowhide, which give the ball durability and a good grip.

-

Seam formation :

- One of the most important steps is the stitching. The stitching is done by hand or machine with red thread. An official match ball has 108 stitches, 54 stitches each that join the two halves of the ball. The number and placement of stitches greatly affect the aerodynamic properties of the ball.

The difference between hand sewing and machine sewing

The seams on the ball are formed in two ways: by hand or by machine.

Each method has its own characteristics and advantages.

-

Hand Sewing :

- Hand-stitching is a method in which skilled craftsmen carefully sew each individual thread. This method ensures great precision and quality. Hand-stitched balls are ideal for pitchers and hitters because the stitching is tight and the ball has a uniform height and width. Hand-stitched balls are also more aerodynamic and fly in a more predictable manner.

-

Machine stitched :

- Machine stitching is a method suitable for mass production, allowing balls to be produced quickly with consistent quality. Machine stitched balls are widely used as practice balls and amateur balls because they are less expensive. However, the precision and feel of the stitching can be inferior to that of hand stitched balls, so hand stitched balls are preferred for professional matches.

Quality Control and Inspection Standards

Strict quality control and inspection are essential to ensuring the quality of baseballs.

Below we introduce our main quality control and inspection standards.

-

Material Inspection :

- We closely check the quality of the leather and threads we use to ensure that the materials are free of defects and have the right durability and performance.

-

Dimension and weight inspection :

- The ball is measured to ensure it meets official regulations for diameter and weight, with a diameter between 2.86 inches and 2.94 inches and a weight between 5 ounces and 5.25 ounces.

-

Seam inspection :

- Make sure the number and placement of stitches is accurate – it’s important that the stitches are uniform in height and width and consistent across the entire ball.

-

Elasticity and resilience testing :

- We test balls for proper bounce and elasticity, which helps ensure consistent hit distances and pitch speeds.

-

Aerodynamic testing :

- We test the ball’s flight trajectory and rotation characteristics to evaluate its performance in real games, ensuring the ball moves predictably.

Overall, the number of stitches on a baseball and how they are formed has a significant impact on the performance and quality of the ball.

By understanding the difference between hand and machine stitching, and our rigorous quality control and inspection standards, players can choose the ball that will help them perform better.

Utilize the latest manufacturing techniques and quality control to play your best.

Recent research on stitch count and future prospects

The number and placement of stitches on a baseball is a constant subject of research because it has a significant effect on pitching and hitting.

Thanks to the latest research and technological advances, ball performance continues to improve.

Here we take a closer look at research into the effect of seam count on performance, new technology and ball improvements, a look at the future of baseballs and the role of seams.

A study into the impact of seam count on performance

Recent research has looked into the impact the number of seams on a baseball has on pitching and hitting.

The main results are summarized below.

-

Relationship between rotation speed and orbit :

- The number and placement of stitches has a significant effect on the spin rate of the ball. A ball with a high spin rate tends to fly straighter and is harder for hitters to hit. Research has shown that the more stitches there are, the more stable the spin rate becomes.

-

Aerodynamic properties :

- The height and placement of seams affect the aerodynamic properties of the ball. A ball with higher seams creates more drag on the air and can have a less predictable trajectory, reducing the batter’s reaction time and making the ball more difficult to hit.

-

Spin rate effects :

- Spin rate is directly related to ball movement, and research shows that proper seam placement can optimize spin rate and maximize the effectiveness of the pitch, resulting in sharper curveballs and more power on fastballs.

New Technology and Ball Improvements

With the introduction of new technology, baseballs are continually improving.

Below we will introduce some of our latest technologies and examples of their applications.

-

High-precision sewing technology :

- The latest sewing technology improves the uniformity and precision of the stitching, which stabilizes the ball’s aerodynamic properties and improves throwing and hitting performance.

-

Nanotechnology Applications :

- Nanotechnology has been applied in the development of new materials to improve the durability and performance of the ball. For example, cover materials using nanofibers are lighter and stronger than conventional materials, improving the distance and spin performance of the ball.

-

Sensor Technology :

- Some balls are equipped with built-in sensors that can collect pitching data in real time, allowing pitchers and batters to analyze their performance and get feedback to improve.

The Future Outlook of Baseball and the Role of Seams

The future of baseballs is expected to continue to evolve with further technological innovation and research.

Below, we explain the outlook for the future and the role of stitching.

-

Optimized for performance :

- The number and placement of stitches will be optimised to further improve the ball’s performance, which can be achieved through more precise manufacturing techniques and advanced research.

-

Use of environmentally friendly materials :

- The introduction of new environmentally friendly materials allows for the production of eco-friendly balls, which provide high performance whilst reducing the environmental impact.

-

Integration with digital technology :

- The development of balls that incorporate digital technology will enable more detailed analysis of players’ performance, improving the quality of training and encouraging players to improve their skills.

-

Customizable balls :

- In the future, balls may be developed that can be customised to suit the individual needs of each player, allowing them to use the ball that best suits their playing style and maximise their performance.

Baseball manufacturing and research has made great strides with technological advances.

By understanding how the number and placement of seams affects performance and incorporating new technologies, the sport of baseball will continue to evolve.

It is important to utilize the latest research findings and technological innovations to pursue the possibilities of baseballs of the future.